Bisphenol-A Epoxy Resin

Specifications

Bisphenol-A Epoxy Resin(Liquid)

| Model | Appearance | Epoxy equivalent,g/eq | Viscosity,mpa.S/25℃. | Hydrolytic chlorine,ppm | Inorganic chlorine,ppm | Volatile,% | Color |

| SM827 | Transparent liquid | 178-185 | 8000-12000 | ≤0.05 | ≤5 | ≤0.18 | ≤90# |

| SM827H | 178-185 | 8000-10000 | ≤0.01 | ≤5 | ≤0.18 | ≤90# | |

| SM828 | 184-194 | 11500-15000 | ≤0.1 | ≤5 | ≤0.18 | ≤90# | |

| SM828L | 180-196 | 9000-12500 | ≤0.05 | ≤5 | ≤0.18 | ≤90# | |

| SM828H | 184-194 | 11500-15000 | ≤0.01 | ≤5 | ≤0.18 | ≤90# | |

| SM828R | 184-194 | 13000-15000 | 0.4-0.6 | ≤5 | ≤0.18 | ≤90# | |

| SM828S | 205-225 | 20000-24000 | 2.0-2.5 | / | ≤0.1 | ≤90# | |

| SM815CA | 195-215 | 800-1600 | 1.7-1.95 | / | / | ≤90# | |

| SM828U | 185-186.6 | 12000-14000 | 0.018-0.028 | / | ≤0.1 | ≤35# | |

| SM828N | 182-192 | 11000-14000 | ≤0.05 | ≤5 | ≤0.18 | ≤90# | |

| SM618 | 184-200 | 10000-25000 | ≤0.5 | ≤50 | ≤1.0 | ≤1 | |

| SM6101 | 210-244 | / | ≤0.5 | ≤50 | ≤1.0 | ≤1 |

Bisphenol-A Epoxy Resin(Semi-solid)

| Model | Appearance | Epoxy equivalent,g/eq | Softening point ,℃ | Hydrolytic chlorine,ppm | Inorganic chlorine,ppm | Volatile,% | Color |

| SM634 | Transparent semi-solid without obvious mechanical impurities | 178-185 | 21-27 | ≤0.5 | ≤50 | ≤1.0 | ≤1 |

| SM634R | 230-270 | / | ≤0.1 | ≤10 | ≤1.0 | ≤1 | |

| SM634H | 245-270 | / | ≤0.1 | ≤10 | ≤1.0 | ≤1 | |

| SM634L | 215-245 | / | ≤0.1 | ≤10 | ≤1.0 | ≤1 | |

| E-39D | 238-256 | 25-29 | ≤0.01 | ≤15 | ≤0.5 | ≤40# |

Bisphenol-A Epoxy Resin(Solid)

| Model | Appearance | Epoxy equivalent,g/eq | Softening point ,℃ | Hydrolytic chlorine,ppm | Inorganic chlorine,ppm | Volatile,% | Color |

| SM638 | Transparent semi-solid without obvious mechanical impurities | 286-400 | 40-55 | ≤0.5 | ≤50 | ≤0.5 | ≤1 |

| SM601 | 450-560 | 60-76 | ≤0.5 | ≤100 | ≤0.5 | ≤1.5 | |

| SM601-R | 450-500 | 65-75 | ≤0.1 | ≤10 | / | ≤1 | |

| SM602-R | 600-700 | 82-92 | ≤0.1 | ≤10 | / | ≤1 | |

| SM603-R | 800-900 | 91-102 | ≤0.1 | ≤10 | / | ≤1 | |

| SM603-RP | 700-835 | 85-98 | ≤0.05 | ≤10 | / | ≤1 | |

| SM604 | 740-1000 | 85-95 | ≤0.2 | ≤100 | ≤0.3 | ≤1 | |

| SM604R | 900-1000 | 96-107 | ≤0.1 | ≤10 | / | ≤1 | |

| SM604F | 740-870 | 90-95 | ≤0.05 | ≤50 | ≤0.3 | ≤0.5 | |

| SM604RF | 740-800 | 90-96 | ≤0.03 | ≤50 | ≤0.3 | ≤0.5 | |

| SM604H | 720-1000 | 90-106 | ≤0.15 | ≤10 | ≤0.3 | ≤1.5 | |

| SM607 | 1700-2500 | 115-135 | ≤0.5 | ≤50 | ≤1.0 | ≤2 | |

| SM607R | 1300-1700 | 117-127 | ≤0.1 | ≤10 | / | ≤1.0 | |

| SM609 | 2400-4000 | 130-150 | ≤0.5 | / | ≤1.0 | ≤2 | |

| SM609R | 1800-2500 | 129-145 | ≤0.1 | ≤10 | / | ≤1.0 | |

| SM609S-1 | 2100-3300 | 110-130 | / | / | ≤0.1 | ≤1.0 | |

| SM6091 | 2200-2900 | 130-150 | ≤0.05 | / | ≤0.5 | ≤1.0 | |

| SM-019 | 2500-3100 | 125-140 | ≤0.05 | / | ≤0.5 | ≤1.0 | |

| SM-020 | 3500-5500 | 135-150 | / | / | ≤0.5 | ≤1.0 |

Packing & Storage

| Packing | In 200KG drum or as per customer’s requirement |

| Storage | Store in dry,clean place ,avoid direct sun-light . |

| Shipping | In room temperature |

Free Quote

At present, the company has more than 10 experienced export sales .

For samples, pricing, or more information, please call us at 0086-25-52397808 or mail to info@pvccopolymer.com . We will respond to you as soon as possible.

Tel: 0086-25-52397808

E-mail: info@pvccopolymer.com

General Information

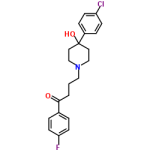

| Common Names | Epoxy Resin | ||

| Structure |  | ||

| CAS No. | 61788-97-4 | Flash Point (℃) | 273.8±30.1 |

| Molecular Weight | 375.864 | Density(g/cm3) | 1.2±0.1 |

| Appearance | Liquid/Solid/Semi-solid | HS Code | 3907300090 |

| Solubility | Easily soluble in methanol, acetone, cyclohexane, ether, etc., and insoluble in water and petroleum solvents | Autoignition Temperature (℃) | 435 |

| Safety Phrases | S24/25-S61 | ||

| RIDADR | NONH for all modes of transport | ||

| WGK Germany | 3 | ||

| Packaging Group | III | ||

| Hazard Class | 9 | ||

| SYMPTOMS | PREVENTION | FIRST AID | |

| Inhalation | Cough. Sore throat. Redness. Burning sensation. Itching. | Use local exhaust or breathing protection. | Fresh air, rest. |

| Eyes | Redness. Pain. | Protective gloves. | Rinse opened eye for several minutes under running water. Then consult a doctor. |

| Ingestion | Abdominal pain. Nausea. Vomiting. | Do not eat, drink, or smoke during work. Wash hands before eating. | Rinse mouth. Induce vomiting (ONLY IN CONSCIOUS PERSONS!). Refer for medical attention . |

Frequently Asked Questions

Bisphenol A liquid epoxy resin: It is obtained by polycondensation of bisphenol A and epichlorohydrin under the action of sodium hydroxide. It is a yellow to amber, viscous liquid at room temperature. It is easily soluble in organic solvents such as ketones, esters, aromatic hydrocarbons and dioxane. High bonding strength, wide bonding surface; excellent electrical insulation; high mechanical strength; good processability; low shrinkage; good stability.

Bisphenol A solid epoxy resin: an essential class of thermosetting resins, widely used in the preparation of coatings, laminates, sealing materials, foam materials and fibre-reinforced plastics, etc., which are used in electrical appliances, electronics, transportation and other fields.